3D Printing Services

3D Printing Services

From Idea to Reality in 3D

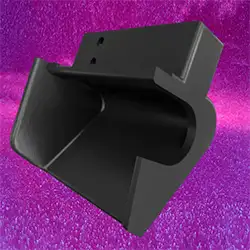

3D Printing Technologies

We offer a range of solutions, including FDM, SLA, and SLS, to create high-quality and customized parts for all your needs.

FDM

Fused Deposition Modeling (FDM) is a popular 3D printing process that uses a continuous filament of thermoplastic material to create three-dimensional objects. It’s widely recognized for its affordability, versatility, and ease of use, making it a great choice for a variety of applications.

LMD/DED

Metal 3D printing has revolutionized the way we create complex and high-strength metal parts. This technology uses a computer-controlled process to build objects layer-by-layer from various metal powders. Its impact has been felt across numerous industries.

DLP

DLP (Digital Light Processing) 3D printing is a powerful technology for creating high-resolution, smooth-surface prototypes and end-use parts. It utilizes a digital projector to cure layers of photopolymer resin, layer-by-layer, to build the desired object.

FFF/CFR

FFF (Fused Filament Fabrication) is a popular 3D printing technology that offers a cost-effective and versatile way to bring your ideas to life. It utilizes continuous plastic filament, similar to a hot glue gun, to build objects layer-by-layer.

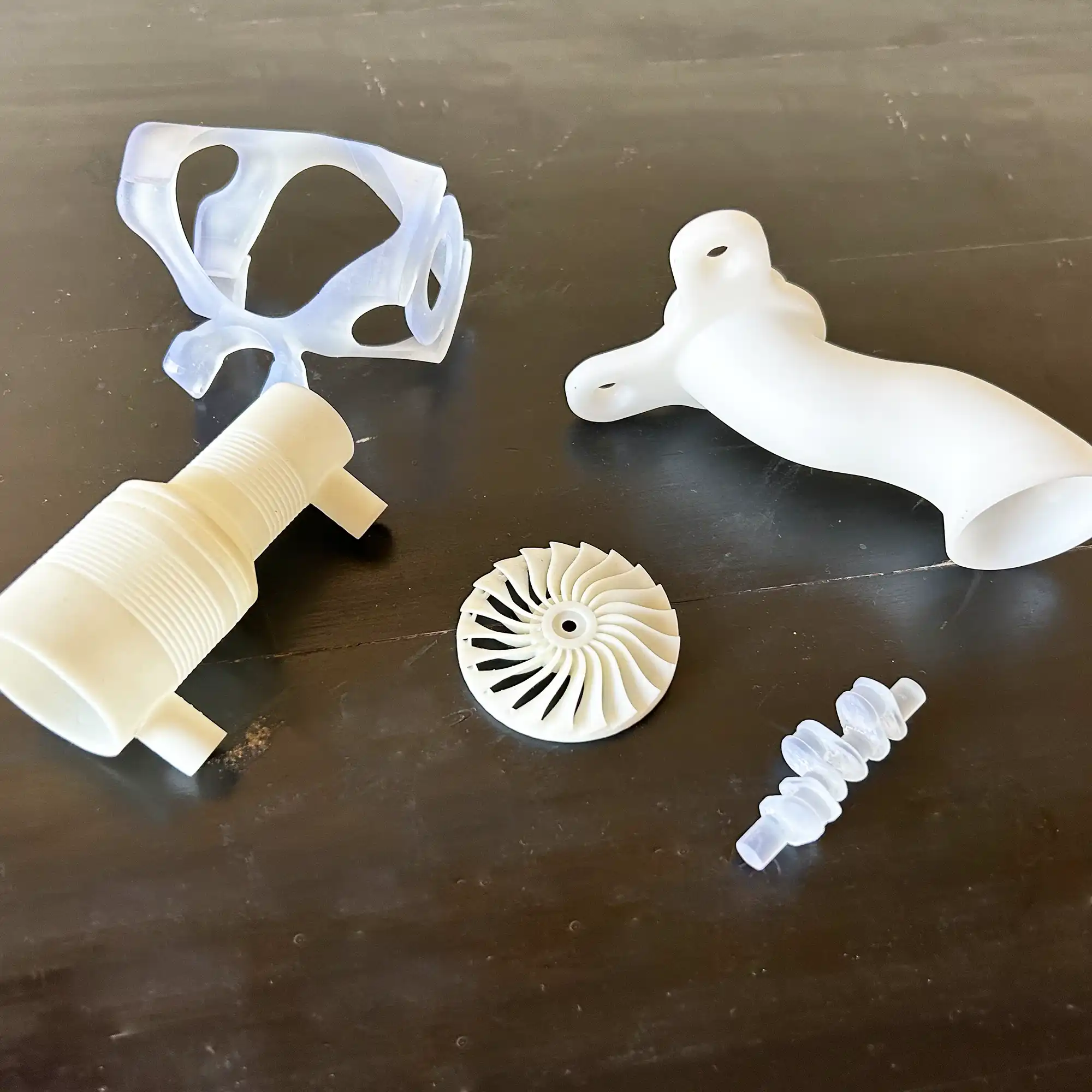

SLA

SLA (Stereolithography) 3D printing stands as a premier technology for unmatched precision and detail. This process utilizes a laser beam to cure photopolymer resin layer-by-layer, creating highly accurate and smooth-surfaced parts.

SLS

SLS (Selective Laser Sintering) is a powerful additive manufacturing technology that creates highly accurate and functional parts from powdered materials like nylon, polyamide, and even some metals. It utilizes a laser beam to selectively sinter (fuse) powder particles layer-by-layer, building objects directly from digital 3D models.